“Run Charts: A Simple and Powerful Tool for Process Improvement,”. “Using Control Charts or Pre-control Charts,”. “Multivariate Control Charts: T2 and Generalized Variance,”. The following are the calculations for diameter, true position format: Resources It is highly beneficial for your metrologist to report the data in X, Y coordinates.

If your data is in form of diameter, true position then the calculation becomes cumbersome and is not supported by a macro. C pk(upper) uses a control chart method to estimate standard deviation, as with an ImR chart and P pk uses the sum of squares estimate, as with a chart.įigure 11: Scatter Plot of Positional Coordinates The only difference in the math between short-term C pk(upper) and long-term P pk is how standard deviation is estimated.

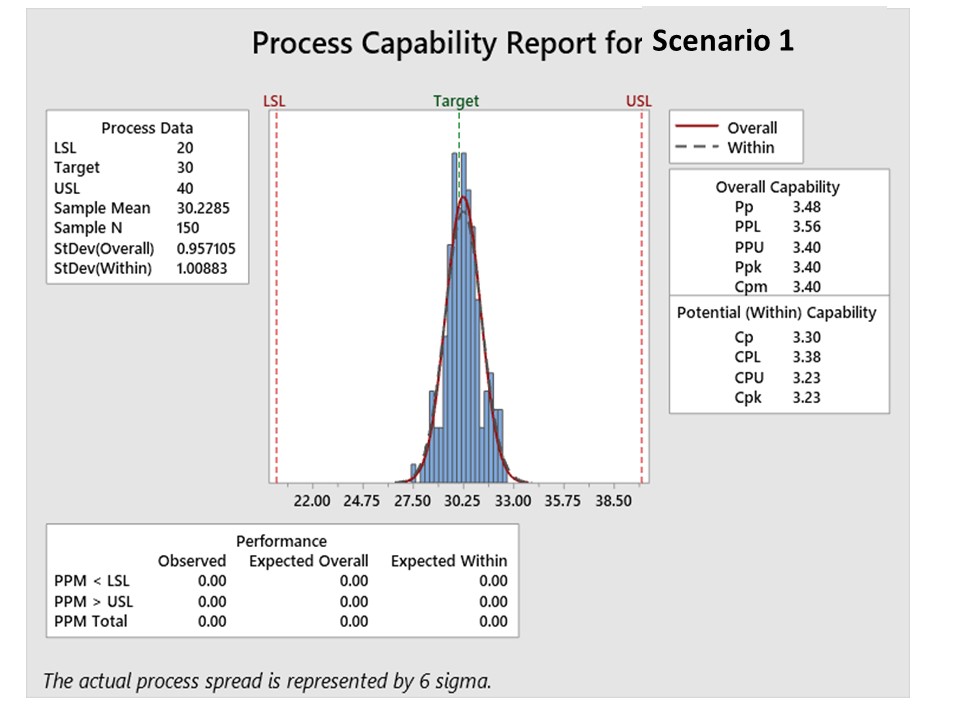

It includes all the data from a number of samplings. It is sometimes called process performance. When all this data is pooled, the distribution is wider. Over time, in each instance, a batch of material is sampled the sample generates a distribution that is shifted from the previous sample distribution. Thus far, the focus has been on potential capability or short-term capability. Convert this to parts per million (PPM) and get a 20,950 PPM fail rate. The probability to fail on the lower side is 2.095 percent. The probability to fail on the upper side is 0 as shown in Figure 5 below. Look up these values on a standard normal table to get the probability of exceeding these values. Where by observation it is shown that Z is 3 times C pk. For the above example, if we see a field failure rate of 5%, then the PCA at the production process probably was much better, 3.14 sigma.Handpicked Content: Resolving Common Issues with Performance Indices The 1.5 sigma shift is meant to be applied to failures observed in the field to extrapolate back to what the PCA estimate originally was.

The answer is that the 1.5 sigma adjustment should not be applied to ppm estimates from process capability analysis. After all, it makes the process look better rather than worse. However, if you enter 50,000 ppm into the sigma calculator it will return a process sigma value of 3.14 because it adds 1.5 sigma to the 1.645 and rounds the result down. If you look up Z for a 5% tail area in a normal table you will find it is approximately 1.645. Let’s say that Minitab’s process capability analysis (normal) shows you the expected overall performance is a PPM of 50,000. Now let me confuse the issue even further. If you wish you can convert Minitab’s PPM data to process sigma by using this calculator.

#Process capability minitab software

We add a fudge factor that assumes that the process will shift by approximately 1.5 standard deviations.” However, when calculating process capability, statistical software such as Minitab will just show what the capability is based on the actual data, i.e., the traditional way. In the lesson on process capability analysis I note that “ in Six Sigma we usually assume that the customer’s actual experience will be worse than what we predict in capability analysis. It does not use the 1.5 sigma “fudge factor” used in process sigma calculations. Process capability analysis has been around a lot longer than Six Sigma. It’s a difference in terminology: process capability versus process sigma. But this time, we are not adding 1.5 to get the sigma level ? Why ? These values are used to evaluate the overall defective rate so that we can extract the Z value.

0 kommentar(er)

0 kommentar(er)